Labelexpo Europe 2017 highlights

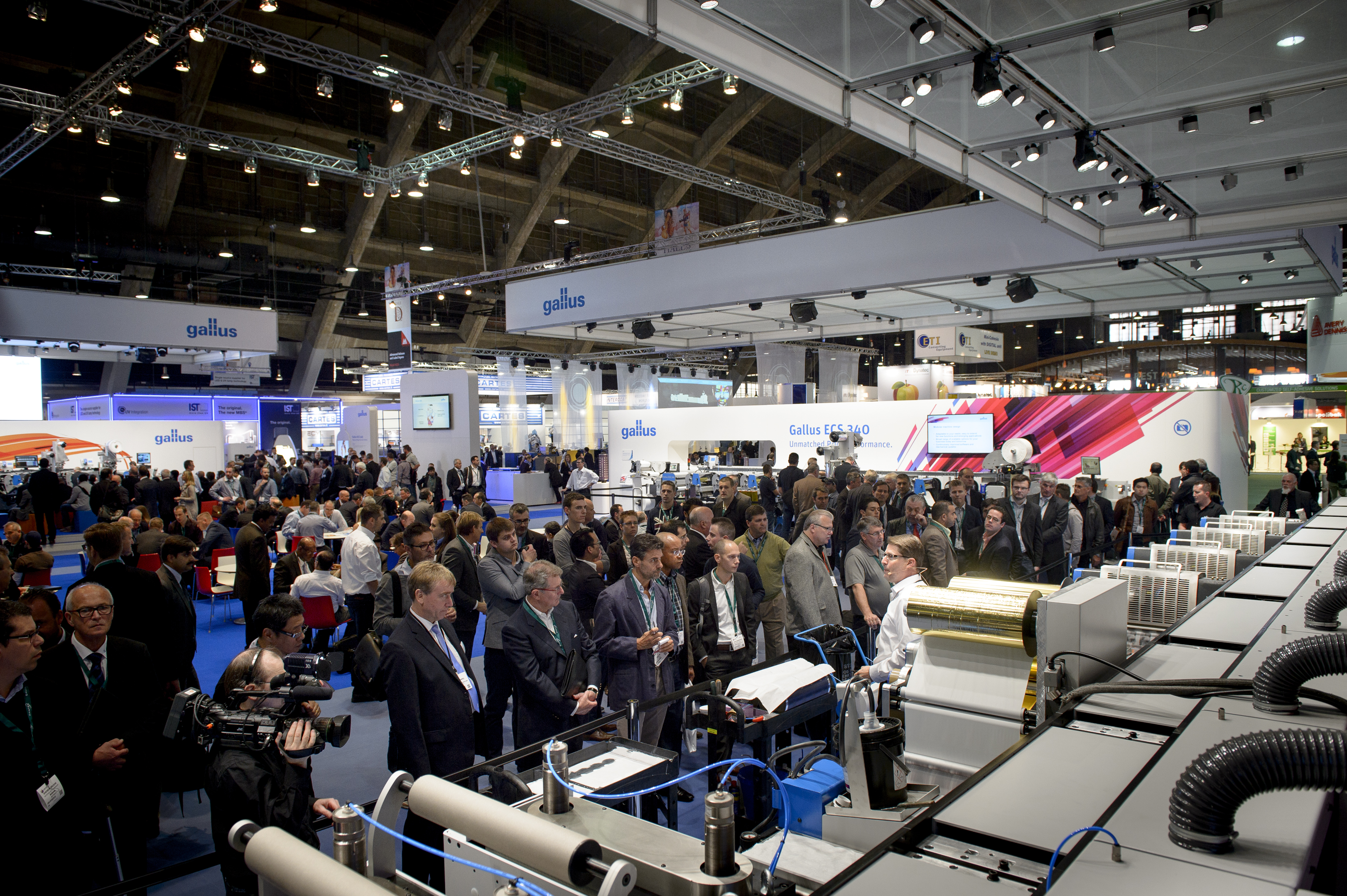

Labelexpo Europe 2017 is gearing up for its biggest edition to date, with the four-day trade show being held during 25-28 September at Brussels Expo. Featuring over 650 exhibitors, the show will highlight the very latest in cutting-edge developments for the label and package printing market.

Aimed at printers, brand owners, label, packaging and graphic designers, Labelexpo Europe is the largest all-inclusive trade fair for label and package printing professionals. Creating a buzz of excitement within the industry, the show covered an unprecedented total of nine exhibition halls.

Buyers attending the show sample the newest tech and next generation materials from over 100 new exhibitors and Labelexpo regulars including: HP Indigo, Avery Dennison, Bobst, Codimag, Domino, Durst, EFI, Epson, Esko, Flint Group, FUJIFILM, Gallus, Konica Minolta, Mark Andy, MPS, Nilpeter, Omet, Ritrama, Screen Europe, SPGPrints, Sun Chemical, UPM Raflatac and Xeikon.

Buyers attending the show sample the newest tech and next generation materials from over 100 new exhibitors and Labelexpo regulars including: HP Indigo, Avery Dennison, Bobst, Codimag, Domino, Durst, EFI, Epson, Esko, Flint Group, FUJIFILM, Gallus, Konica Minolta, Mark Andy, MPS, Nilpeter, Omet, Ritrama, Screen Europe, SPGPrints, Sun Chemical, UPM Raflatac and Xeikon.

Working with long-standing partner and supporter, FINAT, 2017’s show throws the spotlight on the key issues and opportunities facing the label community with a series of special features. Making its debut, the Automation Arena, shows two automated press lines for digital and conventional label production. A practical workshop where visitors discover how information management, integrated workflow, production automation and robotics are working towards changing the performance and economics of the label and package printing plant of the future.

The Linerless Trail returned with a particular focus on in-house production and new materials. The Label Academy holds master classes on shrink sleeves and MIS and workflow alongside an in-depth workshop on inks and coatings.

Ambitious automation arena at Labelexpo

The special feature areas and workshops at Labelexpo shows have long been one of the key attractions for visitors. Digital printing, laser die-cutting, package printing, the linerless trail and inkjet printing have all been well attended showcase features in the past, and have done much to inform and educate the industry about new developments and technologies.

The special feature areas and workshops at Labelexpo shows have long been one of the key attractions for visitors. Digital printing, laser die-cutting, package printing, the linerless trail and inkjet printing have all been well attended showcase features in the past, and have done much to inform and educate the industry about new developments and technologies.

This year, Labelexpo Europe 2017 promises to provide one of the most ambitious of all the special show features organized to date, bringing together some of the main market leaders in management information systems, workflow and pre-press automation, automated digital and analogue press set-up, sophisticated web inspection, and automated finishing and re-winding solutions ? all coming together in a dedicated ‘Automation Arena’ that will provide show visitors with a state-of-the-art snapshot and pre-view of the, increasingly, automated label printing plant of the future. A future in which everything that can be automated will be automated.

SNAPSHOT OF THE FUTURE

Using large size viewing screens in the Arena, visitors will be able to see in detail all the different job creation, artwork uploading, and MIS order processing steps taking place in a CERM system, then on to the working stages of pre-flighting, quality checks, proofing and customer approval using Esko’s Software Platform and Automation Engine, followed by CERM scheduling, substrate checking, tool ordering, and the sending of JDF files, ready for production on to an MPS EF 439, 8-color press ? with no gear cylinder connection, intelligent pressure setting and zero waste roll change ? which in turn will be fitted with a Kocher + Beck UR Precision 449 U non-stop splicer unwind, AVT Helios inspection and a Rotocontrol RSC 340 WFL slitter and turret re-wind.

Several job files (different jobs to the MPS press) will also be sent to a Xeikon X-800 digital front end for batching, step & repeat and the preparation of job identification, die-cut, inspection and turret re winder barcodes in preparation for running on a Xeikon 3300 with a Laser Die-Cutting unit.

Once the Xeikon press starts its production run the different press operations ? printing, inspection, laser die-cutting and re-winding ? will again be filmed and shown on the large screens, enabling Arena attendees to observe the different identification barcodes in operation, AVT defect detection, laser die-cutting set-up and re-winder automation.

Similarly, when the MPS press starts its production run, the different operations of printing, AVT inspection, die-cutting and defect detection will all be filmed and shown on viewing screens. The printed rolls will arrive at the automated Rotocontrol die-cutting, inspection and turret rewinding unit for job finishing, for which the operator has set-up the new job. This set-up and finishing will also be viewed on the large screens.

The last stages in the job automation process will come back to the CERM operator and attendees will be then taken through warehouse stock location, job picking, allocation of the shipping carrier, printing of a delivery note and advising the customer accordingly. An invoice will be prepared and sent, with a covering e-mail, to the customer. Finally, summary data on the day’s production and sales will all be viewed on the Arena screens.

PROGRAMME SCHEDULE

The Automation Arena, expected to accommodate up to 200 people for each session, will be presenting demonstrations three times each day (11.00, 13.00 and 15.00) on the first three days of Labelexpo. That is the 25, 26 and 27 September, and at 11.00 only on the 28th September. One lucky attendee at each session will receive a complimentary copy of the latest Label Academy book on ‘Management Information Systems and Workflow Automation,’ which will also provide the course handout for a five-hour Master class on the same topic being run at Labelexpo on Tuesday 26th September.

Full content available

Full content available